Suitable for Mobile Equipment – Crushers, Screeners, Shredders, Conveyors

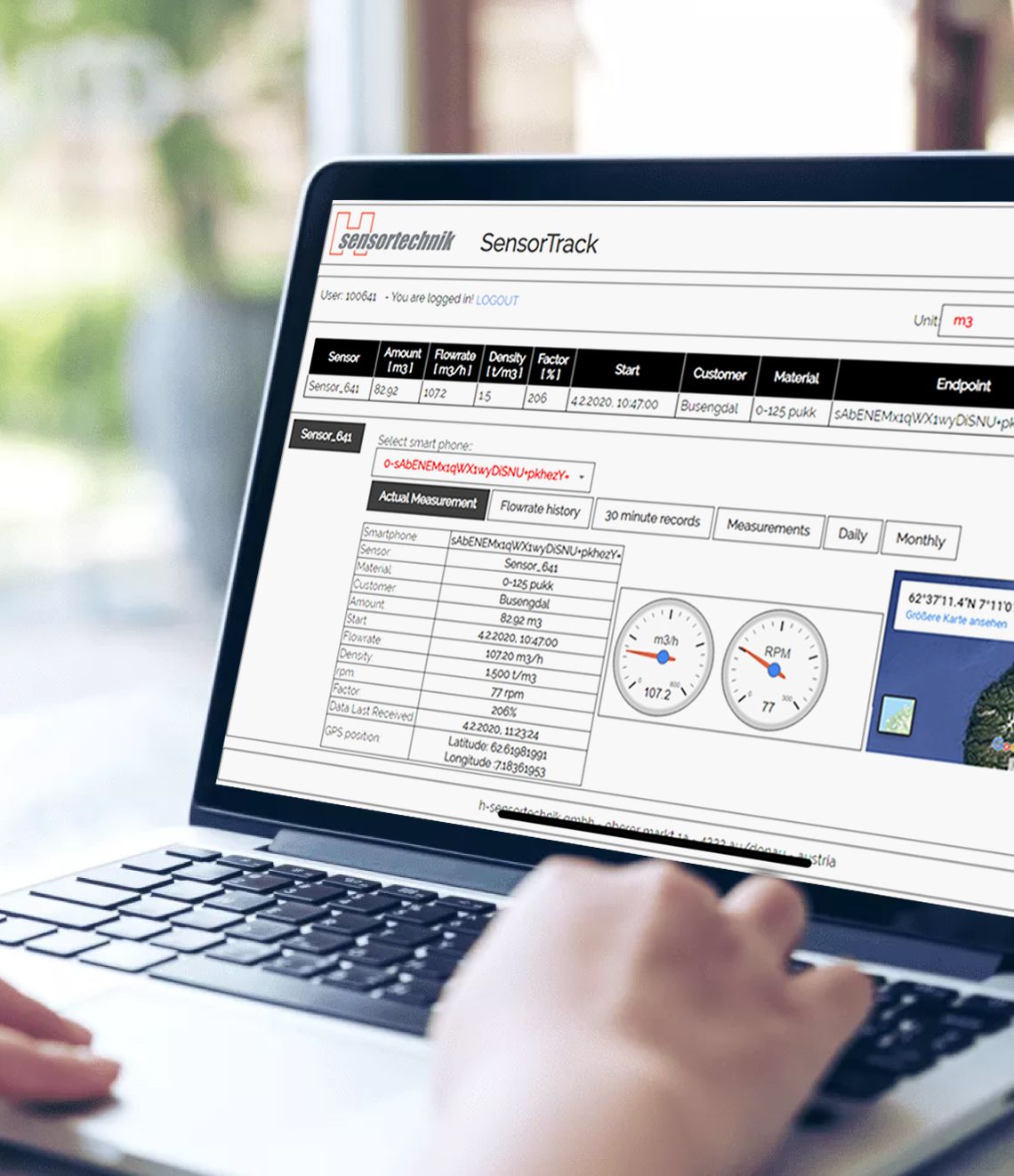

All customer using mobile processing equipment are intrigued to find out the true performance and throughput of their assets. By adding an Optical Belt Scale, they can now accurately manage their production and monitor the true ROI. Additionally if they are a hire or contracting business, the H-Sensortechnik device can be utilised to manage the contract and actual use or tonnage produced.